Aluminium sheets are indispensable across industries like automotive, aerospace, construction, and electronics, thanks to their lightweight nature, corrosion resistance, and high strength-to-weight ratio. However, ensuring the flawless quality of these sheets is crucial, as surface defects such as scratches, dents, and oxidation can compromise both functionality and aesthetics.While manual inspection has traditionally been the norm, it suffers from limitations—subjective judgment, human fatigue, and inconsistency. Today, Machine Vision AI is revolutionizing surface defect detection by offering unmatched speed, precision, and reliability in automated quality control.

Common Surface Defects in Aluminium Sheets

Throughout the manufacturing lifecycle—during production, handling, or storage—aluminium sheets are prone to various surface defects that can affect both their appearance and performance. Accurate detection is critical for maintaining quality. Below are some of the most common imperfections:

- Scratches and Abrasions:

Caused by contact with abrasive materials or rough handling, these linear marks can impact surface treatments like coating or welding. - Dents and Dimples:

Result from mechanical impacts or pressure, creating localized depressions that may hinder fit, finish, or assembly. - Roll Marks and Waviness:

Formed during rolling due to uneven pressure or misaligned rollers, these patterns disrupt surface flatness and consistency. - Pits and Pinholes:

Tiny cavities caused by trapped gas or contaminants; though small, they can lead to corrosion or sealing failures. - Oxidation and Discoloration:

Moisture or chemical exposure can create visible blemishes, often indicating the onset of corrosion. - Inclusions and Foreign Particles:

Embedded debris from raw materials or equipment introduces structural inconsistencies and weak points in the sheet.

Challenges in Aluminium Sheet Inspection in Manufacturing

While aluminium is a preferred material across numerous industries due to its strength-to-weight ratio and corrosion resistance, its distinct physical characteristics introduce significant challenges in surface inspection. Ensuring accurate and consistent defect detection requires addressing the following complexities:

- High Reflectivity:

Aluminium’s naturally reflective surface can cause intense glare and light distortion when exposed to conventional illumination during imaging. This reflectivity often masks surface anomalies and makes it difficult for standard vision systems to capture clear, high-contrast images suitable for defect detection. - High-Speed Production Environments:

In modern manufacturing settings, aluminium sheets often move rapidly through continuous production lines. This necessitates inspection systems that can operate in real time, processing high volumes of data instantaneously without causing slowdowns or bottlenecks in the workflow. - Wide Range of Defect Types:

Surface defects in aluminium vary widely in their nature—ranging from minute scratches to larger dents or structural cracks. They also differ in contrast, size, depth, and location, making them difficult to detect using uniform inspection parameters. This variability demands highly adaptable and intelligent inspection solutions. - Large Sheet Dimensions:

Aluminium sheets commonly span widths greater than 1000 mm, especially in industrial applications. Inspecting such large surfaces with sufficient detail requires advanced, high-resolution imaging equipment capable of maintaining clarity and coverage across the entire sheet width without missing micro-level defects. - Inconsistencies in Manual Inspection:

Human-based inspection is inherently prone to fatigue, subjective judgment, and inconsistency—particularly over extended shifts or high-speed production cycles. As the scale of production grows, manual methods become increasingly unreliable and inefficient, leading to missed defects and compromised quality control.

How Machine Vision AI Overcomes These Challenges

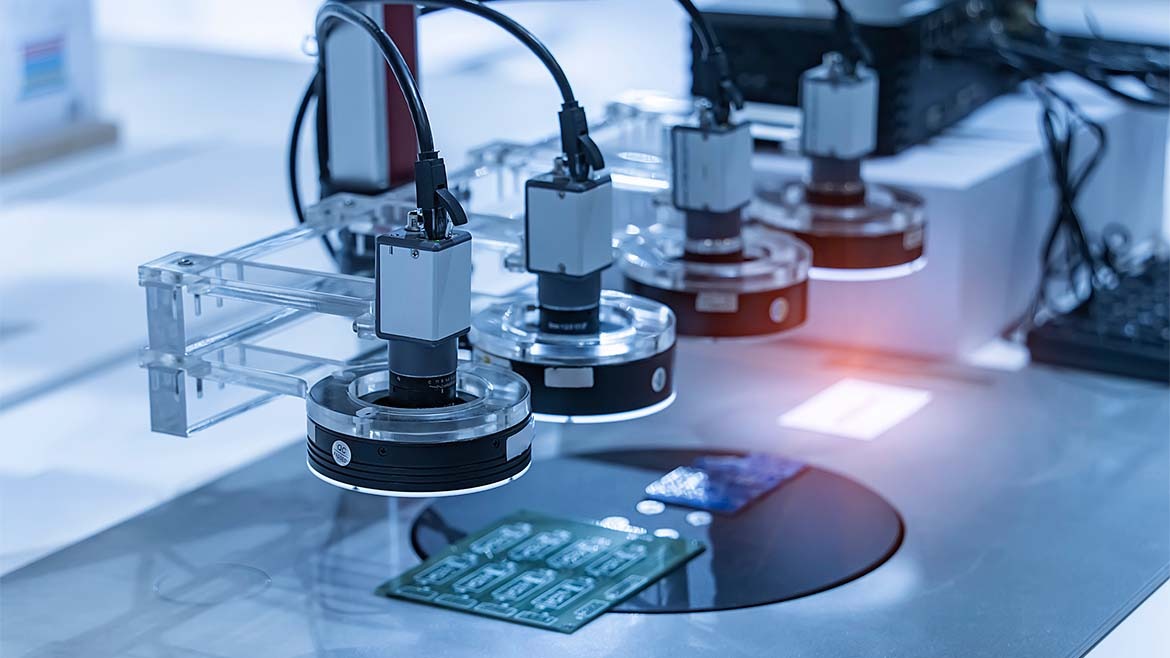

Machine Vision AI leverages deep learning and computer vision to identify and classify defects with speed and precision. The system adapts to new defect types, minimizes false positives, and integrates seamlessly into high-speed production environments.

Key Technologies Include:

High-Resolution Imaging Systems

Accurate surface inspection of aluminium sheets demands advanced imaging technologies capable of capturing fine details across varying sheet sizes and production formats. Two primary camera types are used in machine vision systems, each suited to specific applications:

- Line Scan Cameras:

Designed specifically for high-speed, continuous inspection of wide aluminium sheets—often exceeding 1000 to 2000 mm in width—line scan cameras capture images one line (or row of pixels) at a time. As the sheet moves along the conveyor, these cameras build a seamless, high-resolution image of the entire surface in real time. With micron-level precision, line scan systems are exceptionally effective in detecting even the smallest surface defects without image distortion, making them ideal for continuous production lines and large-format sheet processing. - Area Scan Cameras:

Area scan cameras are best suited for inspecting smaller aluminium sheets or components processed in batches. Unlike line scan systems, these cameras capture full-frame two-dimensional images in a single shot, allowing for quick, detailed analysis of localized regions. Their high spatial resolution and versatility make them well-suited for applications involving static inspection setups or where sheets are briefly paused during the inspection process.

Advanced Illumination for Reflective Surfaces

- Diffuse Dome Lighting:

Provides soft, uniform illumination that eliminates shadows and minimizes harsh reflections, making subtle surface defects easier to detect. - Polarized Lighting:

Reduces specular glare and enhances contrast, significantly improving the visibility of fine surface imperfections. - Backlighting:

Projects light from behind the sheet to create silhouettes, effectively highlighting edge cracks, cuts, and surface deformations. - Structured Light:

Projects patterned light onto the surface to enable 3D profiling, capturing fine texture variations and depth-related defects with high accuracy.

AI Software Capabilities in Surface Defect Detection

Artificial intelligence is revolutionizing aluminium sheet inspection by delivering unmatched speed, precision, and consistency. Integrated with advanced imaging systems, AI-driven software automates the entire quality control process with key capabilities such as:

- Real-Time Processing:

High-resolution images are captured and analyzed instantly as sheets move through production, enabling immediate detection and correction of defects. - Defect Classification:

Smart algorithms identify and categorize issues—like scratches, dents, or inclusions—based on type and severity, helping prioritize quality responses. - Automated Alerts:

The system continuously monitors quality standards and triggers instant alerts when deviations occur, ensuring prompt corrective actions. - Comprehensive Reporting:

Generates visual and statistical reports that highlight trends and quality metrics, supporting data-driven decisions and continuous improvement. - System Integration:

Seamlessly connects with MES and ERP platforms to streamline quality management and optimize production workflows. - Deep Learning Accuracy:

By leveraging convolutional neural networks (CNNs), the software detects subtle and complex defects with high reliability—far beyond the limits of manual inspection.

End-to-End Inspection Workflow

- Sheet Handling:

Aluminium sheets are transported smoothly across automated conveyor systems, ensuring stable positioning and consistent speed for optimal inspection accuracy. - Image Acquisition:

High-resolution cameras, paired with specialized lighting setups, capture detailed images of the sheet surface. These setups are calibrated to minimize glare and highlight surface irregularities. - AI Analysis:

Advanced deep learning algorithms process the captured images in real time, evaluating each sheet for potential defects with high precision and consistency. - Defect Detection:

The system accurately identifies, classifies, and pinpoints defects—such as scratches, dents, or inclusions—based on their type, location, and severity. - Result Display & Action:

Inspection results are displayed instantly on operator dashboards. Simultaneously, the system can trigger automated responses, such as rejecting defective sheets or diverting them for further inspection. - Data Logging:

All inspection data, including defect images and metrics, is securely recorded. This ensures full traceability, supports quality audits, and aids in continuous process optimization.

Applications Across Industries

- Automotive:

Aluminium sheets are used to manufacture high-quality body panels and structural components, offering lightweight strength that improves fuel efficiency and vehicle performance. - Aerospace:

Precision-engineered aluminium sheets serve as aircraft skin and fuselage materials, providing durability, corrosion resistance, and the stringent dimensional accuracy required for airframes. - Construction:

Aluminium sheets are employed in building facades, roofing, and architectural elements, combining aesthetic appeal with long-lasting protection against environmental factors. - Electronics:

Used in heat sinks and electronic enclosures, aluminium sheets facilitate efficient thermal management and electromagnetic shielding to enhance device reliability. - Packaging:

High-barrier aluminium foils and laminates protect sensitive products while being lightweight and recyclable, meeting both performance and sustainability goals.

Advantages of Machine Vision AI in Aluminium Sheet Inspection

- 24/7 Uninterrupted Operation:

The system operates continuously without fatigue or breaks, ensuring consistent inspection coverage across all shifts and maximizing production uptime. - Consistent & Objective Evaluation:

Automated inspection removes the variability and subjectivity of manual checks, delivering uniform and unbiased defect detection every time. - Real-Time Analysis:

Capable of processing inspection data instantly, the system keeps pace with high-speed production lines, preventing bottlenecks and enabling immediate quality decisions. - Adaptable to Product Types:

The inspection solution scales seamlessly to accommodate varying aluminium sheet sizes, thicknesses, and conveyor speeds, maintaining accuracy across diverse manufacturing setups. - Minimizes Waste:

By detecting defects early in the production process, the system reduces material scrap and costly rework, improving overall manufacturing efficiency. - Supports Quality Compliance:

Comprehensive data logging and detailed inspection records facilitate regulatory audits, traceability, and ongoing process improvements.

As manufacturers push for higher quality standards and operational efficiency, Machine Vision AI is emerging as a transformative solution for aluminium sheet inspection. By enabling precise, scalable, and real-time surface defect detection, it reduces reliance on manual inspection, improves product quality, and supports smarter, more agile production processes.

Whether you’re in automotive, aerospace, or industrial manufacturing, integrating Machine Vision AI could be the key to unlocking the next level of quality assurance and operational excellence.